Machining Center

The company has four Mitsubishi M-V4Cn machining centers imported from Japan, which can undertake all kinds of machining services such as turning, milling, cutting and drilling, having delivering high machining precision and efficiency.

| Item | Movement Amount | |

| Movement Amount of X-axis | Movement Amount of X-axis | 560mm |

| Movement Distance from Spindle | ±280mm | |

| Movement Amount of Y-axis | Movement Amount of Y-axis | 410mm |

| Movement Distance from Spindle | ±205mm | |

| Movement Amount of Z-axis | Movement Amount of Z-axis | 460mm |

| Movement Distance from Spindle Nose to Table | 150~610mm | |

Heat Treatment

Vacuum Heat Treatment Furnace Imported Japan

Resume:

The vacuum quenching furnace adopts anoxic treatment, has no carburization and decarburization, and uses vacuum, being safe and pollution-free. It is computer-controlled, has uniform structure and hardness as well as good repeatability, and can meet the heat treatment requirements for all kinds of steel. The greatest feature of the furnace is that it can automatically run and continuously treat without moving the treated object from the beginning of quenching to the end of tempering.

Gas Quenching Furnace Manufactured by NACHI

Resume:

The gas quenching furnace adopts anoxic treatment, has no carburization and decarburization, and uses neutral gas, being safe and pollution-free. It is computer-controlled, has uniform structure and hardness as well as good repeatability, and can meet the quenching requirements for all kinds of steel.

Tempering Furnace Manufactured by NACHI

Resume:

The tempering furnace is suitable for all kinds of quenched steel. The reflector plate is arranged in the furnace to make rectification and wind speed uniform and prevent the influence of radiation, the temperature distribution is uniform in the furnace, and the furnace is computer-controlled and has uniform structure and hardness as well as good repeatability.

Quality Characteristics of Heat-treated Product

The quenching and tempering furnaces of the company can conduct heat treatment for various kinds of steel. Taking high-speed steel (W6Mo5Cr4V2) as an example, the quality characteristics of the quenched and tempered product are shown in the following figure:

Quenching

The hardness is more than HRC64.

Tempering

The hardness is between HRC61~65.

Nitriding

Multinite Furnace Manufactured by TECHNO

Resume:

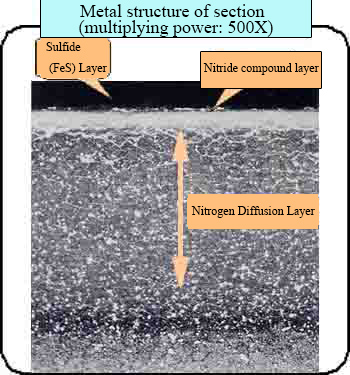

NM gases (H2S, etc.) make the surface of the product activated before nitrification and make the sulfide diffused on the surface of the product while nitriding. The initial adaptability and friction properties (through solid lubrication) are improved by the formation of sulfur compounds (sulfide) at the outermost surface of the product. The furnace is computer-controlled, and has uniform structure, hardness and nitriding layer as well as good repeatability.

Features and Advantages of Multinite

The raw materials for Multinite include N2, NH3 and NM gas, the nitriding temperature is 400-620℃, and the treatment time is 3-5 hours.

Multinite has the following advantages: good abrasion resistance, ablation resistance, occluding resistance, fatigue strength, corrosion resistance and vibration control.

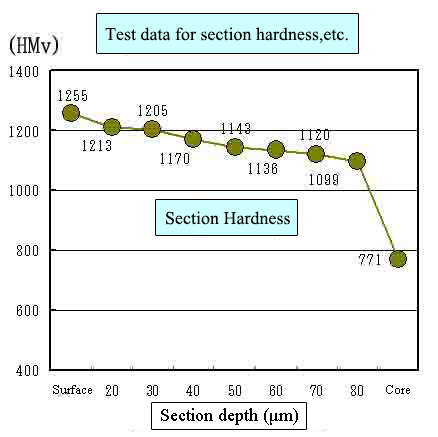

Evaluation of product section (SKH51 + high-temperature Multinite)

Depth of Nitride Layer

| Position | Compound Layer | Diffusion Layer |

| Value(μm) | 12.0 | 140.0 |

Section Hardness(HMv-100g)

| Section Depth (μm) | Surface | 20 | 30 | 40 | 50 | 60 | 70 | 80 | Core |

| Hardness(HMv) | 1255 | 1213 | 1205 | 1170 | 1143 | 1136 | 1120 | 1099 | 771 |

Result:

①The thickness of the compound layer is about 12 μm, which is more than predicted thickness (SUS).

②Depth: surface layer to 80μm, Hardness: 1,000HMv.

Detecting Instrument

The company has a full set of imported testing equipment for quality confirmation after heat treatment, including Surface Mirror Polishing Machine, Metal Microscope, Rockwell Hardness Tester, Vickers Hardness Tester (the photos are shown as follows), etc., having complete testing means.The structure can be clearly observed, and the surface hardness of the product can be accurately measured.

Rockwell Hardness Tester

Metal Microscope

Vickers Hardness Tester

Surface Mirror Polishing Machine